The rise of cloud computing has made having an IoT edge device on your building site an essential component of the IoT architecture.

Continue readingOptergy Air Wireless Sensor Range Launch

Bring your environmental data together with the Optergy Air wireless wall sensor range, your sophisticated solution designed for ease and flexibility.

Continue readingNational Indoor Air Quality Awareness Month

Get informed this National Indoor Air Quality Awareness Month! It’s not a choice, it’s a necessity.

Continue readingComplete Smart Building Controls Launch

Looking for simple and cost-effective building control options? Take complete control of your building with the P864 smart building controls family.

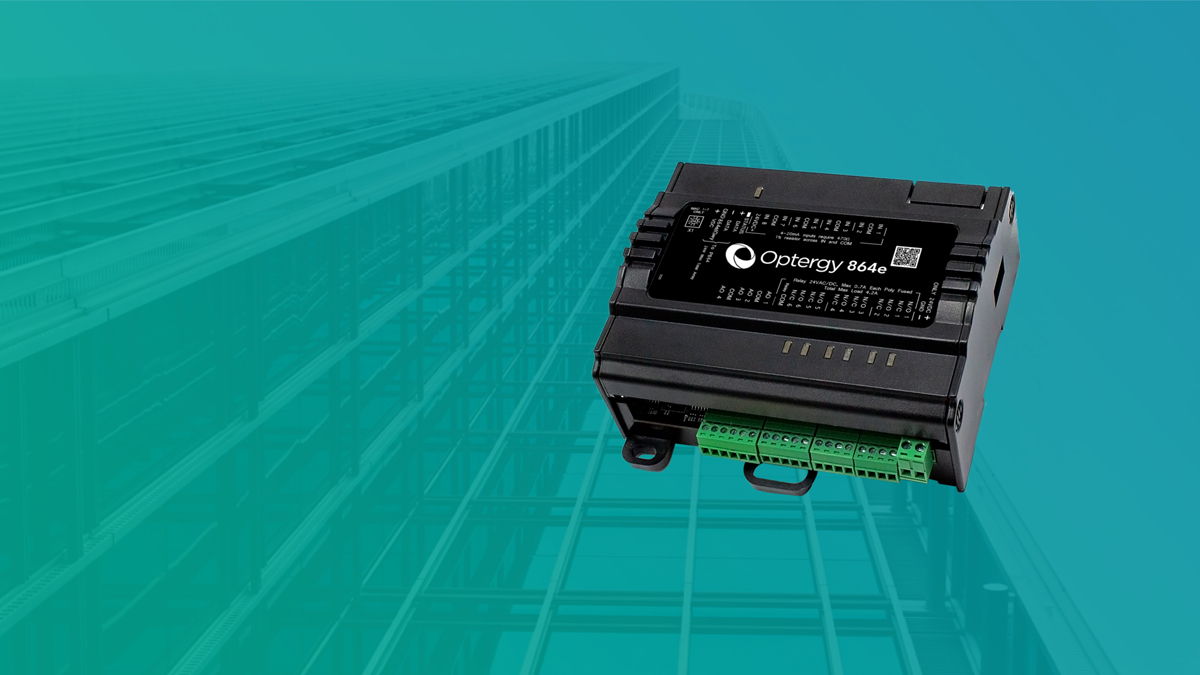

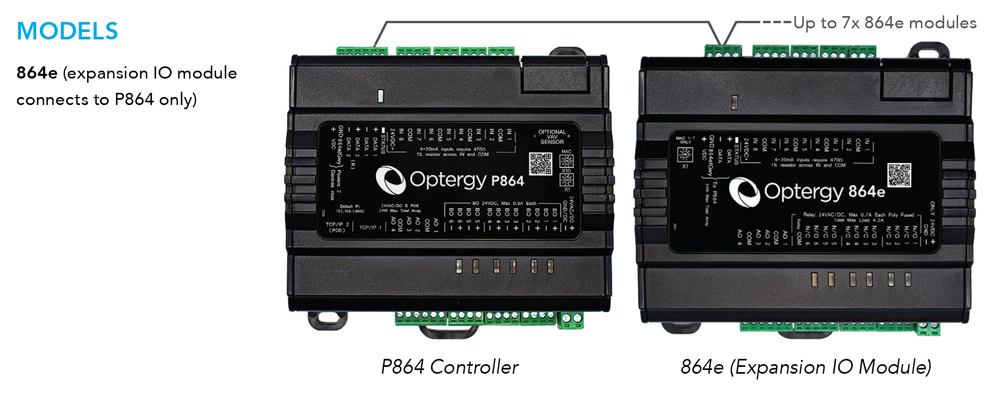

Continue readingAmplify your applications with the 864e Expansion IO Module

Amplify your building applications with 864e Expansion IO Module

An input and output expansion module for use with the P864 controller

If you manage a building, then you know how powerful it is to have seamlessly integrated building applications.

Introducing the perfect P864 companion, the 864e, the ‘e’ stands for expansion. The P864 already fits a lot of applications on its own, but when more inputs and outputs are needed for applications like central plant or as a small building controller. A single P864 controller can be expanded using 1 or more 864e modules to create up to 144 hardware points. The expansion makes the BTL listed P864 a very versatile and scalable controller product. Find out more about the P864 smart edge controller.

More time saving, less time wasting

Each 864e supports:

• 8 universal inputs (thermistor, 0-10V, 4-20mA, raw counts, dry contact, or pulse inputs)

• 6 binary outputs (relay contacts NO/NC)

• 4 analog outputs (0-10V or 4-20mA)

Each of these outputs can be used in conjunction with a DDC program running in the P864.

The data points are instantiated using BACnet and interoperable across the BACnet network.

Designed to be contractor friendly, each 864e has the same footprint as the P864 and can be installed the same way. The connections are in the same place making it easiest to wire and save time at installation.

Safeguard your operations

In the event of communication loss between P864 and 864e, Optergy’s thoughtful design has enabled a backup mode of operation where the device can continue operating at its last known value or in a predetermined fail-safe mode of operation. The device will signal any loss of communication for fast and easy troubleshooting. Diagnostic LED will also blink to let users know its current state of contentment.

All the setup can be done using a built-in web user interface or using Optergy Proton or Optergy Enterprise.

Get started with P864 & 864e

At last, you can have a controller that is just the right size for the needs of your day. To learn more check out the P864 Smart Edge Controller.

Start saving time and enhancing your customer’s building controls by delivering the P864 & 864e Expansion IO Module today. Contact us to find out more about becoming an Optergy Reseller and get started with the Optergy product suite today.

Optergy P864 is BTL Certified

Optergy P864 is

BTL Certified

Announcing BTL Listing for the P864 Smart Edge Controller

Optergy is proud to announce that the P864 is now BTL listed and BTL certified as a

B-AAC (Advanced Application Controller). BACnet Testing Laboratories (BTL) is the authority worldwide that assures interoperability between vendors verified through independent testing.

BTL certification is an important credential that states Optergy P864 conforms to a standard, and that when coupled with the Optergy BACnet PICS, users can be assured of specified interoperability.

A mark of distinction, the BTL mark represents exceptional product quality and conformance achieved after successful rigorous independent testing. These tests validate that the product correctly implements a specified set of BACnet features and identifies and eliminates implementation errors before a product reaches the market.

The P864 was carefully designed to provide simplified engineering and programming, building owners and contractors now have a complete standardized solution for smart controls, smart metering, utilities billing, after-hours billing, automated reporting, live dashboards and foyer displays.

The Optergy P864 connects to Optergy software to offer more than 50+ built-in applications. The P864 operates building equipment autonomously expandable up to 144 I/O points. Connectivity is made easy via BACnet IP (PoE), MS/TP, and MS/TP routing. The P864 is truly versatile, and can also be managed by 3rd party devices or software using its built-in Modbus gateway or REST API. Integrating applications include systems such as HVAC, central plant, VRF, lighting, hydraulic systems, along with energy, water, gas monitoring.

Combining Energy and Building Management Systems to Improve Asset Performance

Optimise Performance by Combining Energy and Building Management Systems

The whole of energy management and building automation is greater than the sum of both parts

Introduction

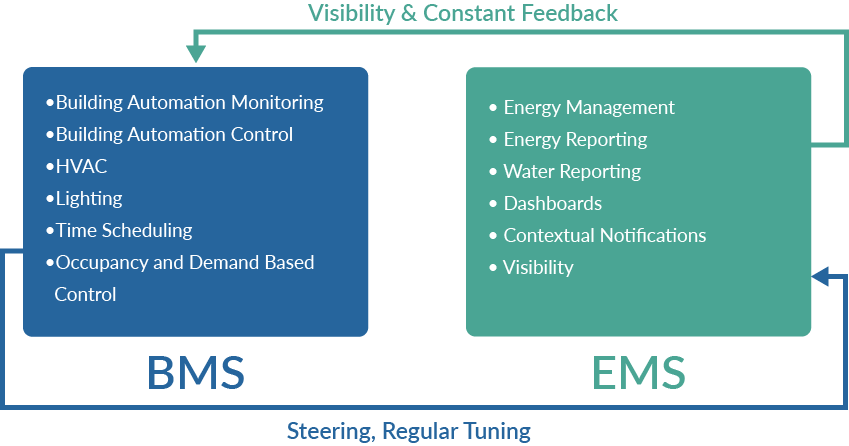

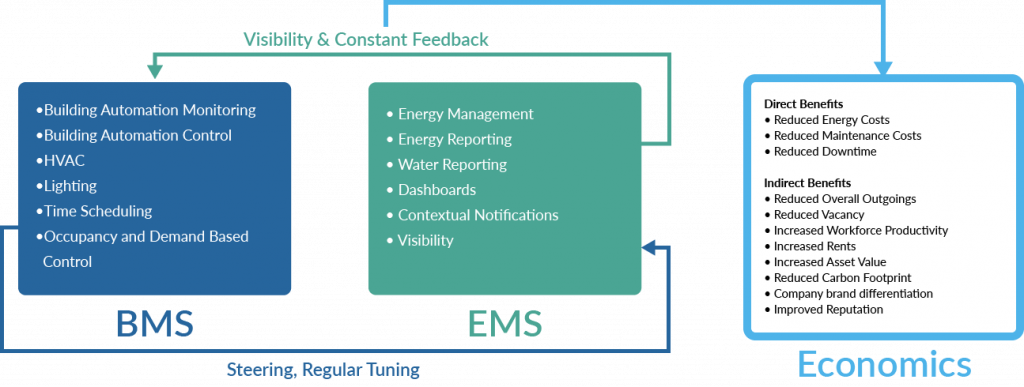

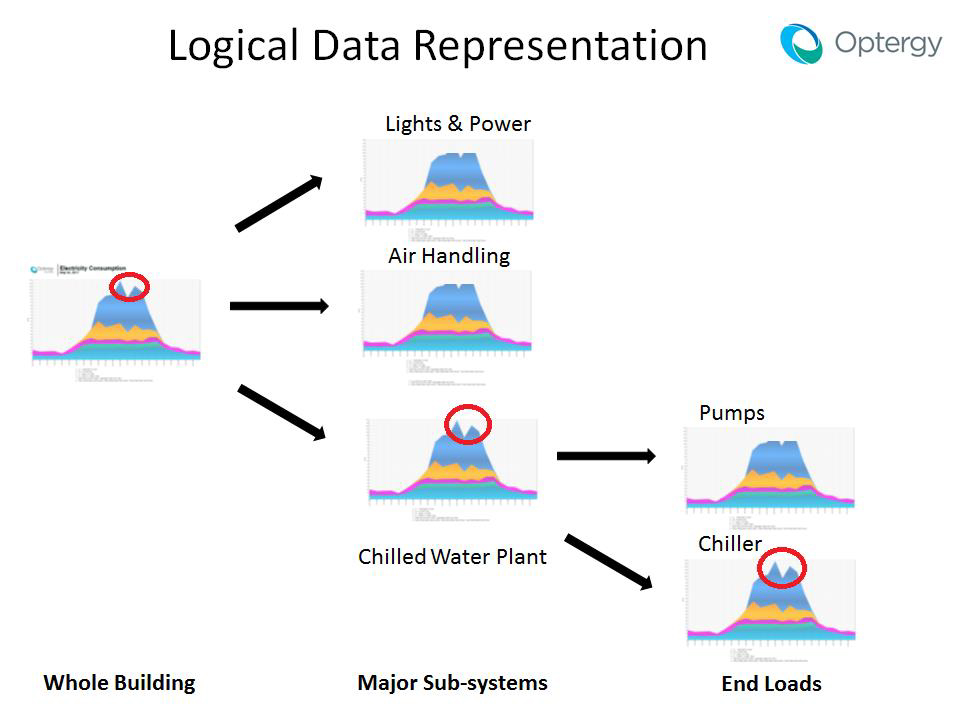

This article explores using energy management systems (EMS) combined with building automation systems (BMS) to expose opportunities for improved building performance in commercial, retail, educational, government, healthcare and office sectors. Combining both EMS and BMS into the one platform breaks down barriers allowing smarter control strategies and contextual alarms to be generated for building operators. Sharing data between these systems removes a “blindfold” from operators and creates visibility and context enabling a continuous feedback loop not previously possible.

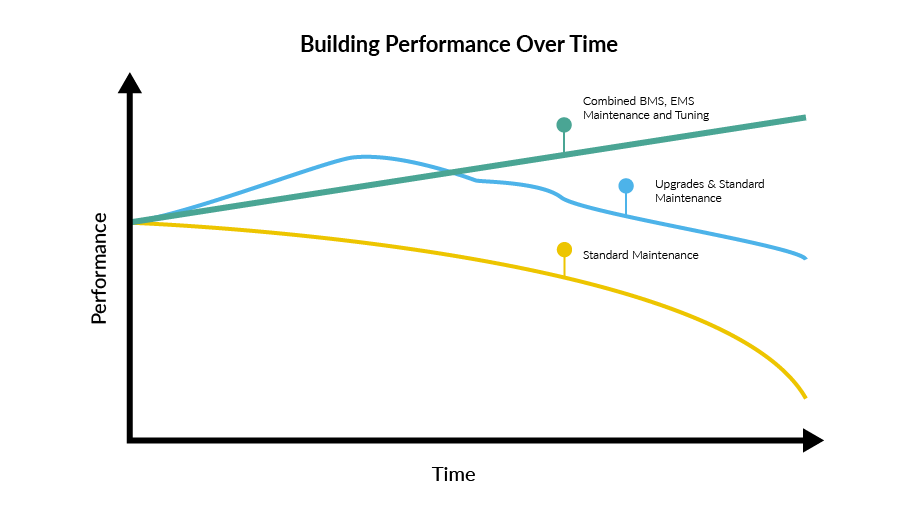

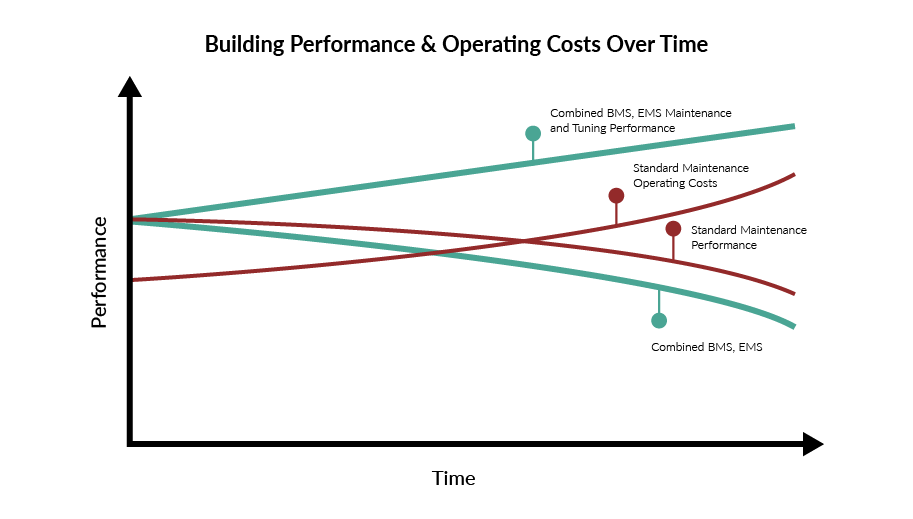

As a consequence of continuous feedback users are able to tune buildings and gain direct benefits including energy savings and reduced operating expenses. This approach replaces performance degradation with a more productive operator who is in control and driving increasing building performance.

The indirect effects of improved building performance can yield far better economic outcomes than just direct benefits. Indirect benefits for a building owner including; longer plant life, less vacancy, faster lease-up periods, higher tenant retention, improved indoor environment quality and workforce productivity. These indirect effects can also drive up asset values, further improving the investment economics for a building owner. (Australian Property Institute, 2012; Fisk, 2000; Fisk et. al, 1997). The whole of energy and building automation is greater than the sum of both parts.

Problem

For years, building systems have consumed energy to keep its occupants comfortable and productive. As a consequence of normal operation, facility managers have faced technical and financial challenges. Managing these challenges to get the right economic outcome has not always been obvious.

We know that buildings are designed to architectural and engineering specifications. However once the building is delivered and the occupants begin using their spaces, it’s not uncommon to find out that the buildings are operated in dynamic conditions. To fulfil the building’s intended purpose, facility management has to juggle numerous operating tasks, such as energy expenses and costs related to maintaining their connected systems.

Competing demands for attention often cause a slow but continued performance degradation. Heating, Ventilation and Air-conditioning systems (HVAC) are high consumers of the building’s energy resources. A HVAC system’s performance degradation can be likened to a slow leak in tire pressure causing premature wear, poor fuel economy and ultimately resulting in breakdown and unexpected costs.

We often see building systems such as EMS, BMS, lighting, security and more that operate as standalone systems, with each as “automated silos” of information. These automated silos result in a lack of insight into how buildings can be utilized at peak efficiency. For example, if a building is unoccupied, the HVAC system is scheduled on and the lighting is left on, we cannot observe the interoperation of systems without sharing information. The result is wasted energy and no information to provide management insight.

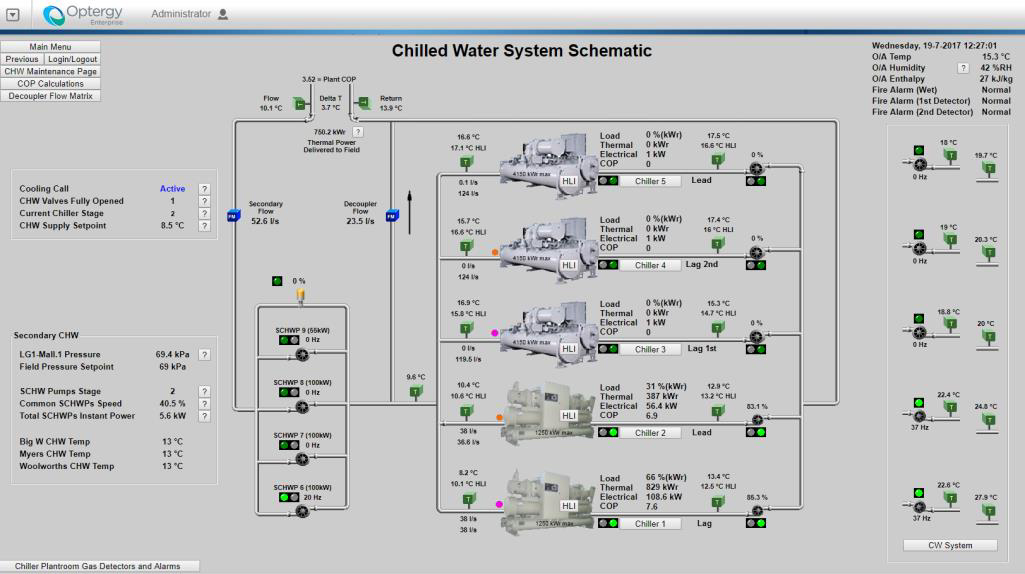

BMS systems are not always on the lookout for problems or inefficient operation. When control problems begin to appear they often manifest as poor energy performance. Troubleshooting is made more difficult when the data lacks context. For example, “Chilled water pump mismatch alarm” or “Chilled water pump increased energy consumption alarm” from siloed systems is not contextual or useful.

All too often BMS systems with frequent alarms become noise generators. With increased frequency of alarm conditions, technicians are often prone to use manual intervention to remediate symptoms rather than the root cause. Symptom remediation and manual intervention inevitably have a compounding effect over time and cause poor performance. Alarms that lack context exacerbate an already difficult situation for building managers as they are not sure which contractor to call for resolution.

Effect

The effect of poor visibility and siloed systems can manifest in a number of ways. Each challenging the buildings economics, and could include but not limited to:

- Increased operating expenses

○ Utility costs

○ Maintenance - Poor comfort conditions causing decreased productivity

- Difficulty attracting premium tenants

- Difficulty attracting investors

- Building asset/Investment is not reaching full potential

Need

To improve building performance, the connected systems need to be dynamic, provide visibility and context in order to drive performance forward. It could be said that operating a building is analogous to driving a car. If the driver has visibility of the road, feedback from gauges and a steering wheel, they will be in full control. Take away the driver’s road visibility or feedback from gauges, they will crash or run out of fuel. Remove the drivers steering wheel and inevitably the car will crash on the first corner.

Why would anyone attempt to operate a building with a BMS system (steering wheel), without an integrated EMS (road visibility and gauges). This would be just like driving a car blindfolded…

Solution

In a building environment we need to make sure that our steering wheel, road visibility and gauges can communicate with each other. Combining both EMS and BMS into the one platform breaks down barriers between previously siloed systems. Sharing data removes the blindfold and creates visibility and context, enabling a continuous feedback loop for building operators not previously possible.

This new-found visibility and context turns what was once darkness and noise, into easily digestible and manageable chunks of actionable information.

For example, what was previously “Chilled water pump mismatch alarm” or “Chilled water pump increased energy consumption alarm” from siloed systems, is now “Chilled water pump operating outside of normal hours without after-hours call from tenant. This has added an additional 30 kwh of energy consumption. The most likely cause is the pump overridden manually. Select Auto on pump or call building automation technician”.

Now an automation problem manifesting as poor energy performance has been made visible, has context and is now actionable in real time. The operator is now empowered and can quickly self- remedy or call the correct contractor to resolve the issue saving energy and hours of wasted investigation time. With this approach we have now replaced performance degradation with a more productive operator who is in control and driving increasing building performance.

With visibility and control combined, improving building performance is like pulling a car out of stop/start traffic onto the open highway. As the car comes up to constant speed, fuel consumption improves and there is less wear and tear on brakes and tires. Similarly, improving building performance is like breaking away from a stop/start unstable environment towards harmonious stability. As the building becomes more stable at a constant speed, only minor corrections from the operator are required. Downtime, energy costs and operating costs begin to decrease as a result of more stable operations. Furthermore reduced wear and tear on plant equipment increases usable life cycle and decreases capital expenditure on replacement plant equipment.

Less vacancy, faster lease-up periods, higher tenant retention, improved indoor environment quality and workforce productivity can be indirect benefits of increasing building performance. These indirect effects can also drive up asset values, making investment economics for a building owner much more favourable (Australian Property Institute, 2012; Fisk, 2000; Fisk et. al, 1997).

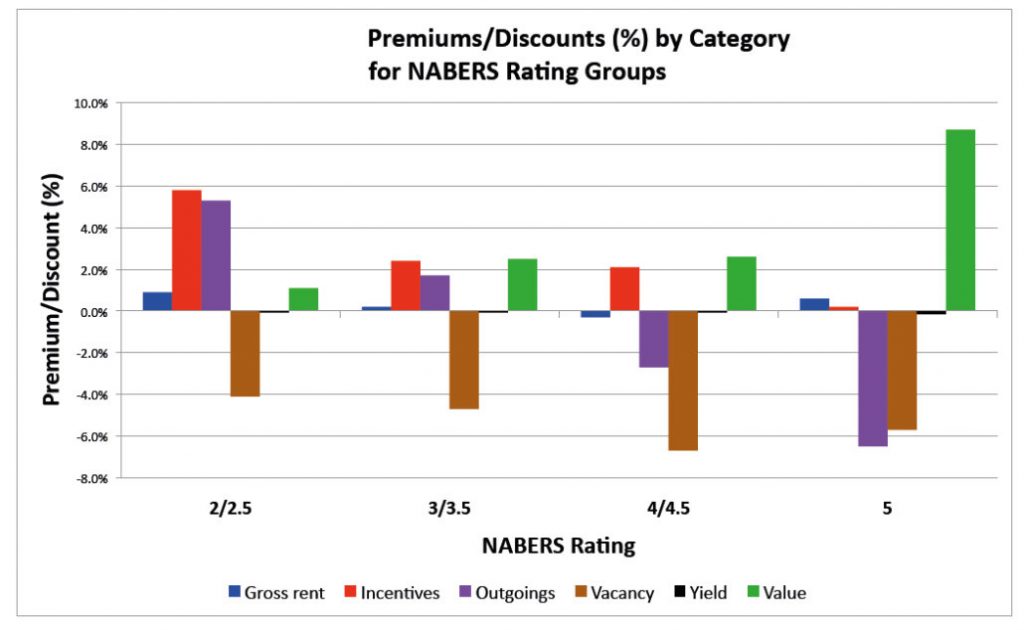

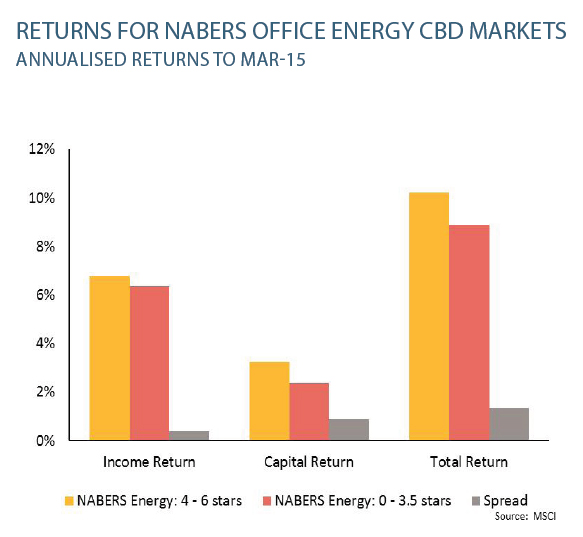

In Australia, the energy performance of office buildings is measured by an energy star rating scheme called NABERS (National Australian Built Environment Rating Scheme). A report published by the Australian Property Institute (2012) quantifies higher office building asset values, reduced vacancy, reduced operating expenses and increased rents due to increased energy efficiency star rating performance.

With this in mind it can be said that the whole of energy and building automation is greater than the sum of both parts, making a strong case for the economics of a combined solution.

It is worth noting that taking a combined approach has another indirect benefit for both building owners and contractors. The building owner receives the benefits of a cheaper bundled solution through shared delivery resources. There becomes one contractor and one source of truth for the delivery of a combined EMS and BMS solution giving the owner a means to hold the contractor accountable for the delivery of a poor performing building.

For contractors, taking on more scope enables them to move up the ‘value chain’, win more work directly with the building owners and ultimately, grow their businesses. To make this strategy work, there needs to be a way for contractors to easily take more scope and deliver it inhouse at a cheaper price than competitors. Consolidating EMS and BMS tools into a single platform helps streamline project delivery and enables contractors to deliver an integrated high performing building to the end user.

The Optergy Solution

Optergy is a technology company dedicated to improving the business of managing facilities and providing tools to improve efficiency, performance and processes. From the simplest building to the largest enterprise, Optergy provide the steering wheel, visibility and gauges required to enable every day building operators to drive high performance buildings.

Optergy is a provider of brand agnostic software that can be installed in a new building or can co-exist with legacy building systems including TRIDIUM, Honeywell, Alerton, Siemens, Delta, Trend, TRANE, Automated Logic, DEOS, Reliable, Schneider, Airtek, KMC, Beckhoff, ABB, Danfoss and most electricity, gas, water and thermal energy meter types available on the market. The software is multi-vendor with a global partner network, has no subscription fees and free software updates with feature additions and improvements.

Optergy in Practice

Top Ryde City Shopping Center

Top Ryde City is a retail shopping center in Sydney Australia. It was originally built in 1957 and was the second open air shopping center in Australia. Showing its age, the center underwent an $800m redevelopment and was reopened by the Prime Minister in November 2009. Due to weak consumer spending and the building’s poor performance causing high costs for tenants, many tenants chose to leave the center.

Subsequently, only 12 months after re-opening the previous owner was forced to sell the newly redeveloped shopping center for $341m ($459m loss) to the international property group Blackstone. Blackstone specialize in buying quality investments at discounts to replacement costs then improve the properties through hands-on management and targeted value-add initiatives.

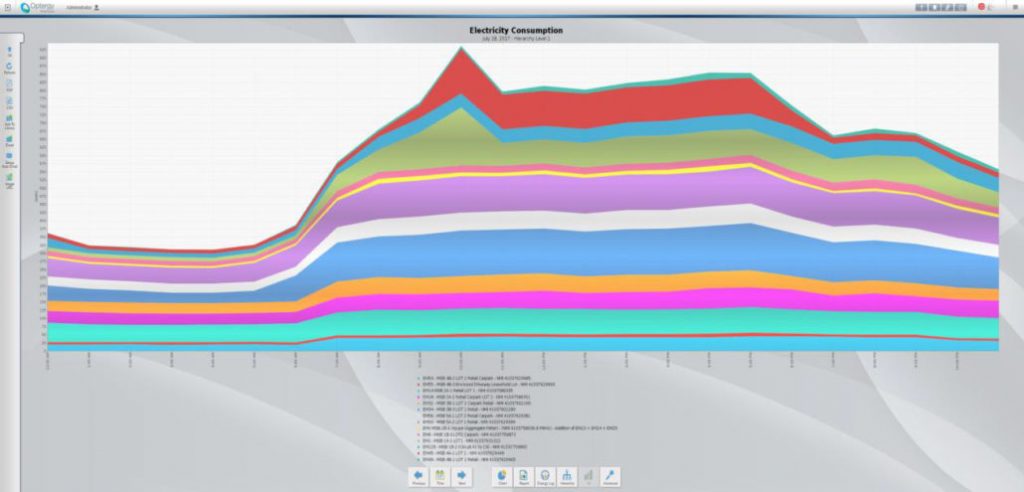

Poor performance was identified as a significant cause of high operating expenses. This highlighted the need to tune up the BMS system and significantly reduce the amount of money spent on energy and maintenance. To enable building tuning and a constant feedback loop for building operators, over 160 sub-meters were connected to the building’s automation system. In this building the automation system controls over 70% of the energy loads, making it the most logical place to provide the operators visibility and gauges to put them firmly in the driver’s seat.

Combining both the EMS and BMS has enabled the operations and maintenance team to tune up the building and implement clever occupancy based strategies in conjunction with energy demand management.

Since implementation, through continuous feedback and tuning the center has seen direct benefits including a cumulative reduction of 4,296 MWh (12.91%) resulting in over $2.2 million of energy savings from the 2014 baseline. A staggering result delivered by Peter Reece, David Irvine and Paul Finny. An amazing operations team equipped with the right tools.

According to advisory firm McgrathNicol, annual net operating income increased from $18 million to $24 million over an 18-month period due to attraction of premium tenants and increased asset performance. Blackstone now have their Australian portfolio for sale and are expecting $700 million from the shopping centres sale. A return of 359m in just 8 years.

Conclusion

It is essential to make sure the steering wheel, road visibility and gauges can communicate with each other in the built environment. Combining both EMS and BMS into the one platform breaks down barriers between previously siloed systems. Sharing data removes the blindfold and creates visibility and context enabling a continuous feedback loop for building operators not previously possible.

Automation problems manifesting as poor energy performance can be made visible, be given context and are made actionable in real time. Empowering building operators to quickly self-remedy or call the correct contractor to resolve an issue, saves energy and hours of wasted investigation time. This approach replaces performance degradation with a more productive operator who is in control and driving increasing building performance.

Energy savings, longer plant life cycles and less operational expense are direct benefits. Less vacancy, faster lease-up periods, higher tenant retention, improved indoor environment quality and workforce productivity can be indirect benefits of increasing building performance. These indirect effects can also drive up asset values making investment economics for a building owner much more favourable (Australian Property Institute, 2012; Fisk, 2000; Fisk et. al, 1997).

This combined approach provides a lower total installed cost and enables building owners to hold the contractor responsible for the delivery of a poor performing building.

The whole of energy and building automation is greater than the sum of both parts.

Literature Cited

Bannister, P (2017). Metering: A practitioner’s perspective. [Powerpoint presentation]. Available at: http://www.cibse.org/getmedia/f82bf2ce-57d1-4fd1-ae37-94d0051828cf/CIBSE-Seminar-Paul-Bannister-pptx.pdf.aspx. [Accessed 10th July 2017].

Blackstone, (2017). Who we are [Online] Available at: https://www.blackstone.com/the-firm/asset-management/real-estate. [Accessed 18th July 2017].

Darby, S. (2006). The effectiveness of feedback on energy consumption. Environmental Change Institute University of Oxford.

Darby, S. (2006). Making it obvious: designing feedback into energy consumption. Environmental Change Institute University of Oxford.

Fisk, W. (2000). Health and productivity gains from better indoor environments and their relationship with building energy efficiency. Energy Environ, 25:537–66.

Fisk, W. et al (1997). Estimates of improved productivity and health from better indoor environments. Indoor Air, 7:158-172. IPD Australia Green Investment Property Index (2013). Headline Results.

McGrathNicol, (2017). Top Ryde Shopping center [Online] Available at :

http://www.mcgrathnicol.com/case-studies/top-ryde-city-shopping-center-2/. [Accessed 19th July 2017].

Newell, G. et al (2012). Building better returns. Australian Property Institute. [Online] Available at: http://www.api.org.au/assets/media_library/000/000/219/original.pdf. [Accessed 20th July 2017].

Roth, K et. al (2005). Energy impact of commercial building controls and performance diagnostics: market characterization, energy impact of building faults and energy savings potential. TIAX LLC, Cambridge, [Online] Available at:

http://s3.amazonaws.com/zanran_storage/www.tiaxllc.com/ContentPages/42428345.pdf.

[Accessed 20th July 2017].

The Property Council/IPD Australia Green Investment Property Index (2015). Green Snapshot Flyer.

Vanda, C (2012). Top Ryde City shopping center sold for rock-bottom price. The Daily Telegraph.

[Online] Available at: http://www.dailytelegraph.com.au/realestate/top-ryde-center-sold-for-rock-bottom-price/news-story/3a4515114d3fe0140aa97394a149bbfc?sv=4e5e26230d5986bd9da0f4d6ee247b76. [Accessed 18th July 2017].

Small Commercial Building Energy Use

Small Commercial

Building Energy Use

Email Interview

By Steven Guzelimian and Ken Sinclair

Sinclair: Why are you interested in small buildings?

Guzelimian: “There is nothing small about the impact that small commercial buildings have on energy use in the United States. In fact, the 4.6 million small buildings across the nation consume 44% of the overall energy use in buildings. This is presenting an enormous opportunity to cut costs, energy use, and greenhouse gas emissions.” http://www.nrel.gov/docs/fy14osti/60917.pdf

Small buildings represent a disproportionate amount of consumption. When you consider the impact we can have as building automation experts, this is the area we should be looking at more vigorously. In my career, I have seen very little activity in these buildings and manufacturers were not catering to this market. When you consider the economics of the small building, controls have always been too expensive. Traditional controls usually meant multiple stand-alone systems that did not even benefit from simple time scheduling on/off or set point adjustment controls for HVAC and lighting.

Sinclair: Small buildings don’t always have technical talent to manage complex BMS/EMS systems? Is it worth the effort?

Guzelimian: Yes. Our challenge as a manufacturer is to build products that people can use. That is economical on the first cost, that deploys easily, and can be maintained by service providers or by the end-users themselves. Manufacturers need to provide the full experience to their customers. Which that means making the tools available to configure the system and all the documents and self-paced e-Learning training. This is needed to realize the benefits of their system economically. The small building often houses a business, and these systems need to enhance their operation. With improved comfort to keep workers productive, increased energy efficiency to reduce operating expenses, and business work-flow improvement to make the business work better.

Sinclair: Building and energy management have been around for years, where does Internet of Things (IoT) fit in small building management?

Guzelimian: Building automation has traditionally connected HVAC, lighting, and access controls, using Standard protocols like BACnet, Modbus, LON, KNX, and others. Integration was usually done with hardware to software integrations (gateways). With recent changes in mobile connectivity, and the desire to connect non-traditional appliances to local networks, there has been interest in making software connections and sometimes host applications on cloud servers that do the processing and provide a user interface. This Internet of Things concept is the mechanism for integration, but on its own does not add value until applications are created that leverage the customer data to gain a customer outcome. Domain knowledge is the key to successful outcomes, IoT is an enabling concept that can help build tools, however, it is standards (ANSI/ISO) that will help bring this together so that dissimilar systems can communicate to one another, and securely. There is more work to do in this area and no shortage of creative energy to launch products.

Sinclair: What happened to Big Data?

Guzelimian: Big data is still there, but as trends go, some things go big and consume resources, and some things go small but provide valuable data. In recent years one of the drawbacks of wireless technologies has been the available bandwidth and the ability to keep its power supply with as little maintenance as possible. There have been successes and flops in wireless technology, but one thing is certain, if you use a lot of data, you will need power and if you do this often at high rates of speed the data usage will grow. One thought here is to right-size the data for the application, if you collect a water meter data, you probably don’t need to ping the value thousands of times, some things are time sensitive but many are not. We should as an industry be pursuing small data, the opportunity is that we can extend battery life and to make managing the data easier. If less is more than Small data is valuable data.

Sinclair: What trends are you interested in?

Guzelimian: We at Optergy are interested in improving outcomes for its customers. Building management systems have sometimes become problem generators; we like to think that we can bring the balance of economics and problem solving together into software features people can use to increase their productivity. After all the building alone does not simply need to be controlled; it is the occupants that also need to be considered and that both should serve the intended purpose and design of the enterprise. We only need to look at the balance sheet of a building as it has income and expenses. The number 1 expense is often Payroll, if we can do even the slightest bit to improve productivity, we have a tremendous impact on the income side of the balance sheet. If we can reduce operating expenses then the value of an owner operated building increases in value when you consider the capitalization rate (a property metric) of the building. http://www.propertymetrics.com/blog/2013/06/03/cap-rate/

Another trend is the growing adoption of energy & building management in developing nations. We at Optergy are working to make products that can be easily localizable; that means not engineering a system use the native language but rather provide a simple translation that can be further customized by the end user simply and with built in web based tools. They used to say all business is local, and that is true, if you don’t speak the local language, it might be that much harder to realize the benefits of automation.

Optergy will be displaying at AHR 2017, Booth #C1075. Optergy’s Theme for 2017 – It’s all about the small building.

View the interview online.

For more information on our software or to become an Optergy reseller partner please visit: www.optergy.com

Optergy wins Light Commercial Solution of the year in Control Trends Awards 2016

Optergy wins Light Commercial Solution of the year in Control Trends Awards 2016

Awards Honors Top Performers in the HVAC, Controls, and

Building Automation Industries

Proton by Optergy won the 2016 Light Commercial Solution of the Year at the ControlTrends Awards, held at the Hard Rock Cafe in Las Vegas on January 29th, 2017.

The Control Trends Awards (CTA), recognises leading companies, products, technology, and individuals in the building automation and HVAC controls industry, judged by a steering committee of industry leaders. Thank you to everyone at ControlTrends for a great evening and we’d like to extend our congratulations to all the other talented winners and nominees.

Proton is a web-based building controller for small to large buildings. It allows integration of diverse systems while focusing on a great user experience. Proton now caters up to 100 devices, has built-in web editing tools, virtual device support and automatic language translation support.

“We are honored to have won the Light Commercial Solution category at this year’s ControlTrends Awards ceremony,” said Steven Guzelimian, president of Optergy. “Optergy continues to focus on driving innovation, especially in the small building space. We are busy building practical products for today and for the future that are innovative and completely web based and yet thoughtful on security.”

To view the full list of ControlTrends Award winners, follow this link.

For more information on our software or to become an Optergy reseller partner get in touch with us at info@optergy.com.

Using IoT to Achieve Better Outcomes

Using IoT to Achieve Better Outcomes

Good outcomes = planning + technology + execution + integration.

Internet of Things (IoT) terminology is relatively new to the discussion as it relates to buildings, in fact, the choice of words does not really convey what it is, how you can use it, and why you should use it.

The IoT three letter acronym is really a catch-all for all devices (controllers or computers), data sources (sensors), and a data stream (historical data) that may include mobile connectivity, monitoring capabilities, standalone control capabilities operate peer to peer, or perhaps even use autonomous operation capabilities.

Experience with buildings was acquired over many years applying new technology, and along the way, knowledge was gained and standards refined. Technology alone does not solve problems but can be a helpful tool to get to a good outcome. It could be said that good outcomes = planning + technology + execution + integration. Buildings and their occupants have a low tolerance for lights turning off or heating not running, so robust reliable tried and true techniques are needed to assure the quality of service.

There can be unintended consequences of deploying IoT technology. Manufacturers and their integrators need to carefully assess their application to make sure that IoT devices do not adversely affect current systems.

IT Security

This is probably the most overlooked requirement that all buildings need to consider. Security related to IoT should be a specification item as buildings are designed and then technologies selected. A fuller description of the different needs are beyond the scope of this article, but here are a few tips if you are tempted to deploy an uncertain technology:

- Does the manufacturer have domain expertise in IT security?

- What is inside the IoT device? (i.e. open source software, web servers, and 3rd party software)

- How often is the IoT device maintained? (i.e. does the manufacturer provide any risk mitigation)

- Does the manufacturer regularly update its end users, (i.e. contractors may be providing these, are the updates timely)?

- What are the connectivity options? (e.g. Wi-Fi, Bluetooth, Zigbee…each brings its own security paradigm)

- If the device is web based, what is the user authentication paradigm? (2-step authentication is becoming more popular as passwords can be cracked with brute force algorithms.)

- At a minimum, the systems should deploy strong passwords, with expiring credentials. Passwords should never be sent in clear text that could be easily intercepted by simple free TCP/IP scanning software.

- If remote connectivity is an option does the system deploy HTTPS (SSL) or have built-in Virtual Private Network (VPN) to secure the connection against man in the middle attacks?

- If the device has ports, like USB, can software be uploaded changing its intended purpose?

Following the deployment of IoT or any building technology, it is advisable to check and recheck periodically that IoT devices have not been connected directly to the internet. A useful tool for this is https://Shodan.IO (search engine for the IoT). It’s quite revealing to see what devices are connected and very visible.

There have been highly publicized malicious attacks like the Target hack which relate to poor user credential management. Another recent example includes IP cameras which sparked a wide-scale internet outage. Simple improvements like strong passwords with expiration dates could prevent many opportunistic attacks. Also physically restricting access to devices that contain intellectual property or valuable customer data would provide a better safeguard.

Facility Maintenance

IoT devices may offer new and interesting ways to interact with building systems and provide insight into building operations. It’s important to keep in mind that the user needs to be adequately prepared to monitor, troubleshoot, and service the IoT devices. Facility managers sometimes face stretched budgets and may be unable or unwilling to commit to ongoing service contracts.

- If the IoT devices use batteries, do they have adequate warning detection and preventative maintenance?

- Are the spare parts readily available and have they been budgeted for at the time of acquisition?

- Does the manufacturer provide comprehensive training for setup, operation, and troubleshooting? Is there an added cost?

- How long does the system or technology get support for?

Economics of IoT

IoT technology can be acquired as a subscription based system often referred to as SaaS (or subscription as a service) or as an on-premise technology where the customer purchases the software or hardware outright and owns the licensing.

- Subscription models can get the users into new technology at a reduced entry price and can get feature updates very quickly as the system is maintained by the provider. For some users, their budgets may not be amenable to subscription models. In some cases, subscription prices may increase as users are added to the system.

- Subscription providers may require end-user intellectual property or sensitive data to be held outside the enterprise. For end users such as banks, healthcare, military, and government this may not be permissible.

- On-premise products are usually provided with a fixed cost for installation and startup. In some cases, this may result in unexpected product and labor costs when new software versions become available.

- Most on-premise systems store data onsite and therefore get managed by local support resources.

Choosing the right system for their next IoT project depends on the customer’s budget objectives. Whether a subscription based or on-premise technology is used for an IoT project, the systems should meet the needs of the capital expenditure budget, as well as fit with the operating expense budget.

Open & Standard Protocols

In order to get the best out of IoT, it needs to coexist with the building systems, and not act as a silo of information like a standalone system. IoT devices should interoperate with known standards and protocols used with building systems. Standards assure the systems operate in predictable ways that facilitate better security, connectivity, and integration.

Standards come in a few varieties, so here are the common ones used in buildings for the last 20 years.

- BACnet (Standard and Open Protocol) is the building automation and control protocol that is open (meaning anyone can develop for it) and standardized by ANSI Standard 135-2012 – BACnet-A Data Communication Protocol for Building Automation and Control Networks.

- Modbus (Open Protocol), is an open standard put forward by an organization that anyone can develop on, there are rules for implementers, but no certification or standards body that governs it.

- N2, Niagara AX & Sedona (Manufacturer Protocol), these are manufacturer created protocols that are sometimes free and open to develop but may have licensing restrictions or costs to deploy.

Leverage existing technology

IoT technology can solve problems when deployed with domain expertise, security, an appropriate cost model, and focused on delivering good customer outcomes.

As you consider IoT products make sure you have domain expertise to realize the goals of the system. Domain experts are usually people from engineering disciplines, technologists, or certified energy managers with first-hand experience applying building technologies in the field.

Current BACnet and Modbus protocols have a lot to offer, with known risks. Users may be able to achieve new applications and improve comfort and productivity with existing systems. Direct Digital Control systems have been around for years providing the infrastructure to create innovative applications and leverage new IoT technology now, and into the future.

This article published online through AutomatedBuildings.com.