Progress Against

Budget Reporting

Optergy’s Building Management System

How to Manage Design Expectations And Reality

With the cost of energy sky rocketing in most developed countries, it’s becoming more and more important to effectively manage its consumption. One of the major problems is that energy is mostly invisible making it hard to see excessive use or waste. The easiest way to think about energy consumption is to compare it to water.

For example; when you take a shower before work in the morning, with a small turn of a tap on the wall you can control the amount of water coming from the shower head. The water can be trickling out slowly or blasting out excessively. As long as the temperature is ok, it doesn’t matter whether the water is trickling or blasting. The outcome is that you have comfortably cleaned yourself in preparation for the day ahead.

Energy is much the same. If we can see its excessive use, we can adjust the ‘tap’ to trickle and achieve the same satisfaction and outcomes with less energy and cost. The key is visibility.

If you are a building owner, facilities manager or controls contractor in-charge of either an existing building or one that’s been recently delivered from construction and its energy performance is not meeting your expectations, don’t worry you’re not alone.

In most cases during a building’s design phase its energy performance has been modelled. Unfortunately, there is a disconnect between the time of modelling and the delivered building and sub-metering system, making it difficult to correlate the buildings actual performance back to the original model. Due to this disconnect, the detailed breakdown of the building by energy load group is mostly shelved with the operator’s visibility being limited to total building consumption. This single value is then used to benchmark the overall performance back to the model.

Buildings rarely perform as expected, which leaves operators frustrated with the delivered result. With the model on the shelf and only total consumption to benchmark the entire building, the operator is left with limited visibility to drill deeper and understand which load group is consuming in excess. These frustrations lead to tension between operators, designers and contractors along with days, weeks or months of lost time trying to understand the black hole of consumption. As a building operator, you are lucky if these problems are identified during the defects and liability period. The excessive cost of energy you will bear for a short time, but the expensive hours of diagnosis are on the consultant and contractor. If outside the defects and liability period, these costs are on you for the entire period the building performs poorly. In some cases, this can be years.

There is a need to be able to track a building’s designed energy model against its actual performance. Building operators need three things to be able to achieve this.

Designed energy model by load group

The building’s sub-meters broken down by load group; and

Ability to track each load group against the designed energy model

Using an energy monitoring system, it should be easy to sub-meter the various pieces of plant and then aggregate together to create load groups. Then the model for each load group can be entered and tracked against. Load group types include (not limited to):

Chiller Plant

Air Handling

Car park Ventilation

Toilet and General Ventilation

Lifts

Lighting

General Power

With this approach operators can see at a glance which load groups are performing as expected and which are not. From here operators know where to concentrate their efforts and can drill down to the source of a problem quickly. This is a great way for existing buildings to gain visibility and then turn the ‘tap’ down to trickle to begin their journey towards high energy performance and lower overall costs.

For new buildings this method enables a source of truth and analytics on how systems perform all the way from the design phase, to delivery and day to day operation.

In both scenarios this saves hours of time on diagnosis and highlights load groups which are consuming energy excessively, causing higher than expected utility costs. It also removes blind guess work from building tuning and optimization giving the operator direct feedback of where to focus.

There are many metering systems on the market that can provide the visibility describe. However, Optergy is a software company that does things a little differently providing unique advantages. Optergy allows integration, monitoring and control of a buildings HVAC, hydraulic and lighting systems along with sub-metering systems all on the one platform.

Optergy includes a pre-built energy management application for automated reporting. One of the many reporting options is called Progress Against Budget Reporting. This allows operators to track a buildings design energy model against actual performance.

Using the Progress Against Budget reporting, operators can analyze performance by load group and then make changes to how a buildings HVAC, hydraulic and lighting systems operate all from the same software interface and platform. If issues are found or certain load profiles are not meeting expectations, then HVAC, hydraulic and lighting systems can then be monitored and tuned through one interface, putting the power back into the building operator’s hands.

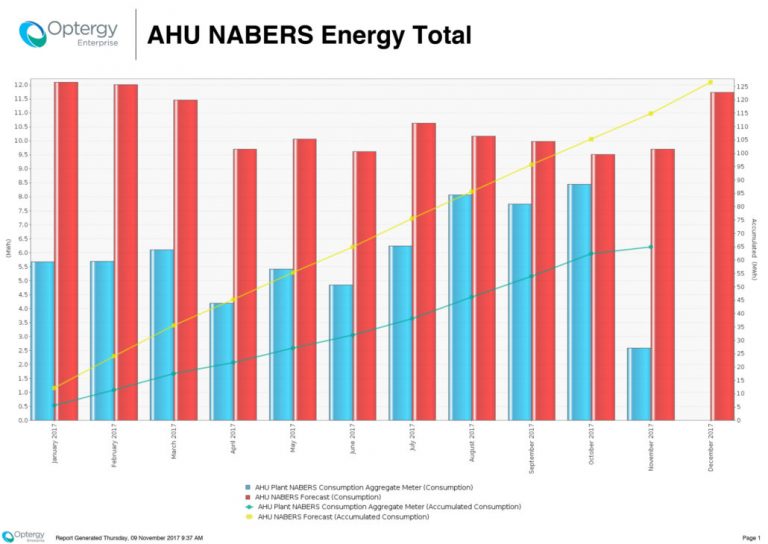

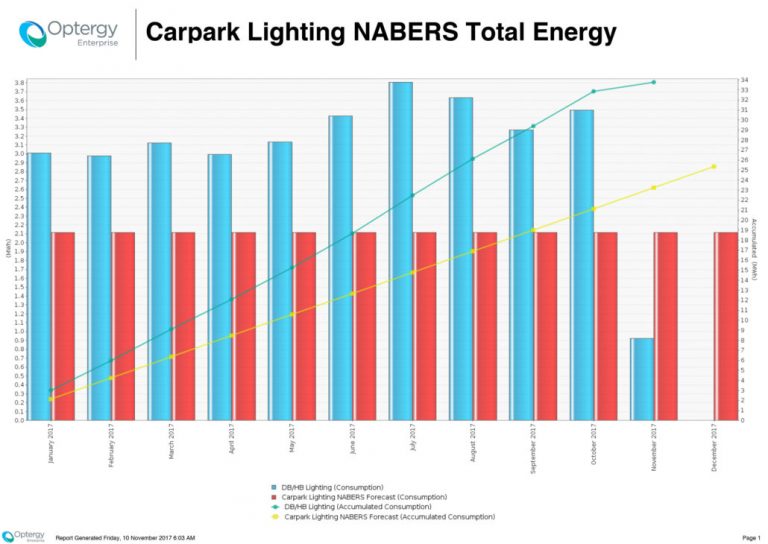

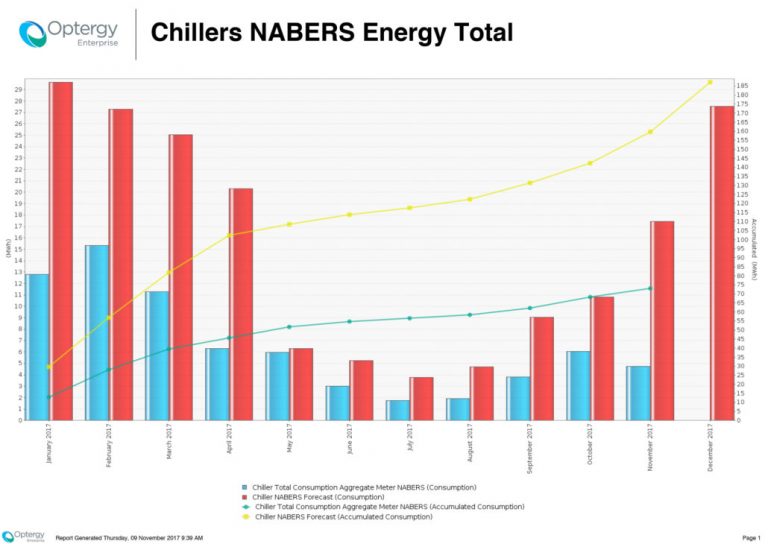

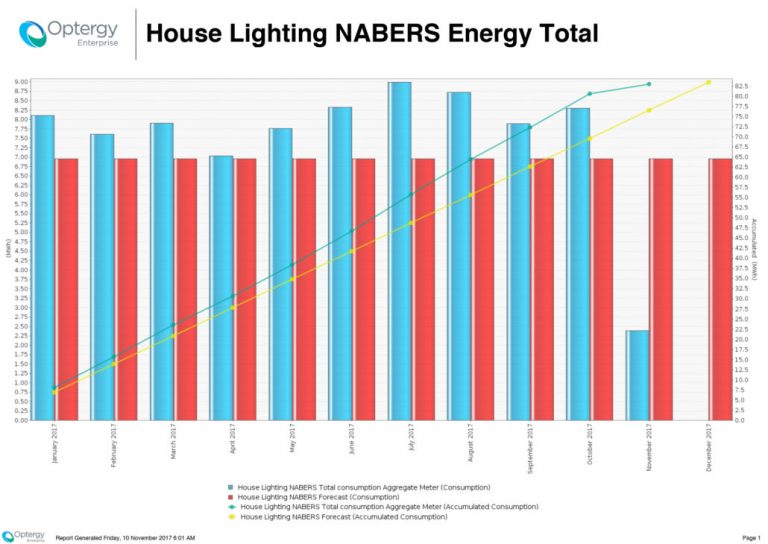

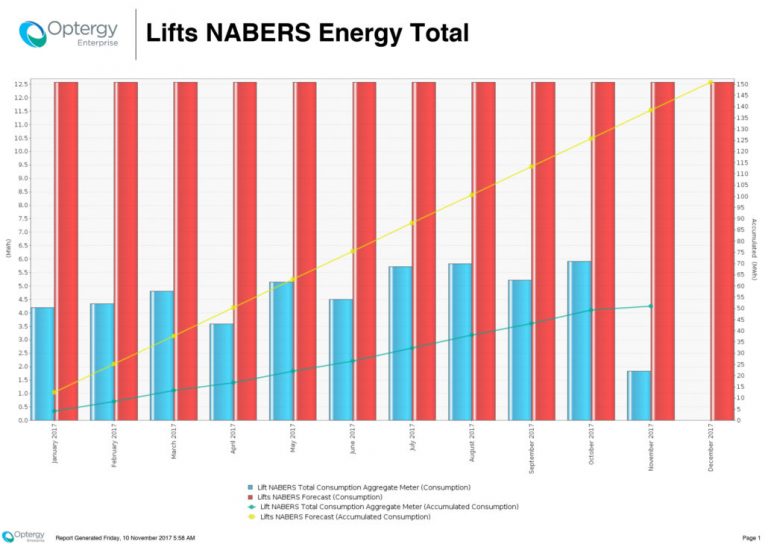

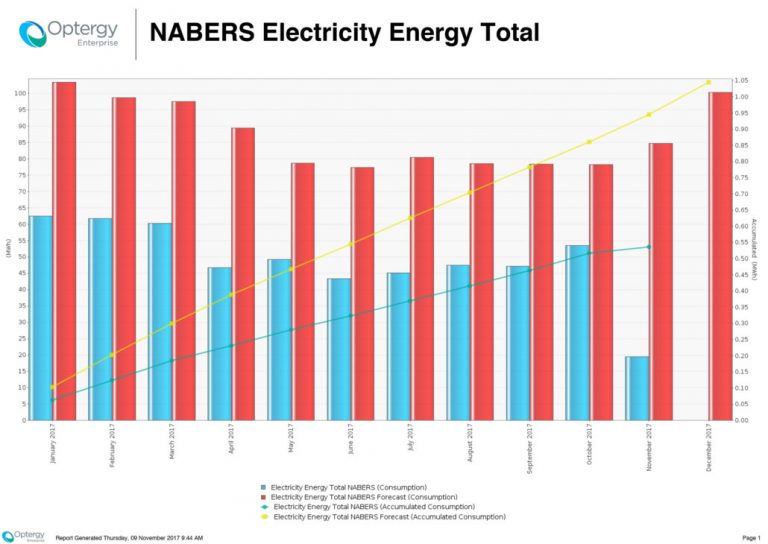

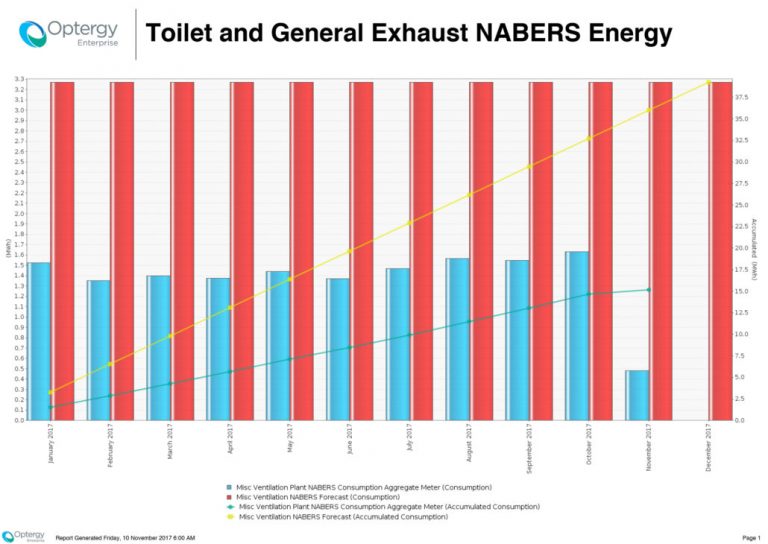

Here’s an example provided by one of Optergy’s channel partners in Australia. This buildings energy model was based on a 5.5 NABERS energy star rating. The energy model was provided by the design consultant to the contractor. The contractor then implemented a sub-metering system which divided the building up by major load group and entered in the design model to track each load group against the design. The blue bars represent actual performance with the red representing the model.